Unlocking the Power of Continuous Fiber Reinforced Thermoplastic Honeycomb Panels: The Future of Lightweight Structures

Release time:

2025-03-31

Author:

Chengzi Tainuo

Source:

Discover the versatility and benefits of Continuous Fiber Reinforced Thermoplastic Honeycomb Panels in construction, automotive, and aerospace industries.

Introduction to Continuous Fiber Reinforced Thermoplastic Honeycomb Panels

Hey there! If you’ve been keeping an ear to the ground about innovative materials in construction and manufacturing, you might have heard whispers about Continuous Fiber Reinforced Thermoplastic Honeycomb Panels. But what exactly are they? Well, buckle up, because we’re diving deep into the world of these lightweight, robust structures that are reshaping how we build and design.

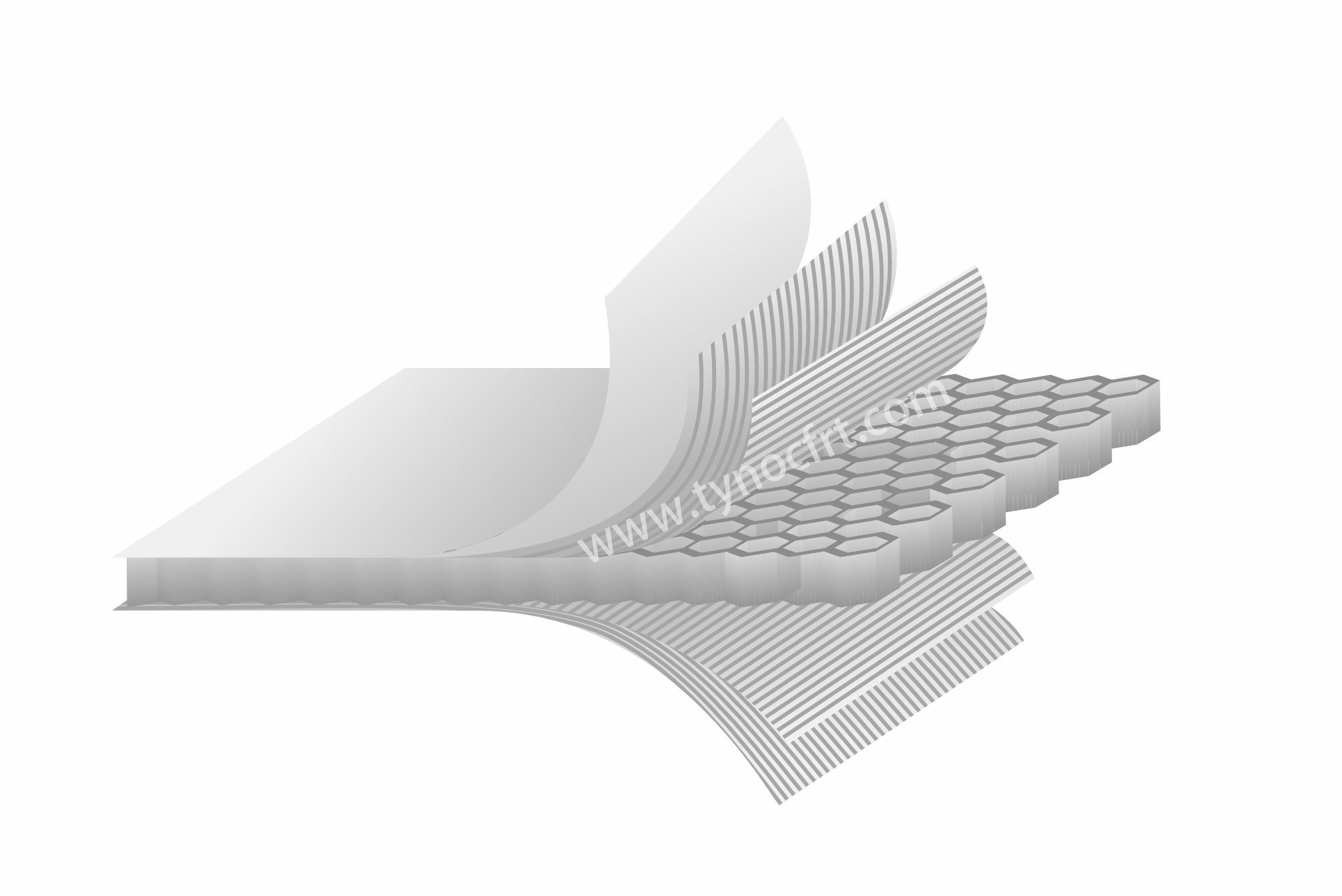

What Are Continuous Fiber Reinforced Thermoplastic Honeycomb Panels?

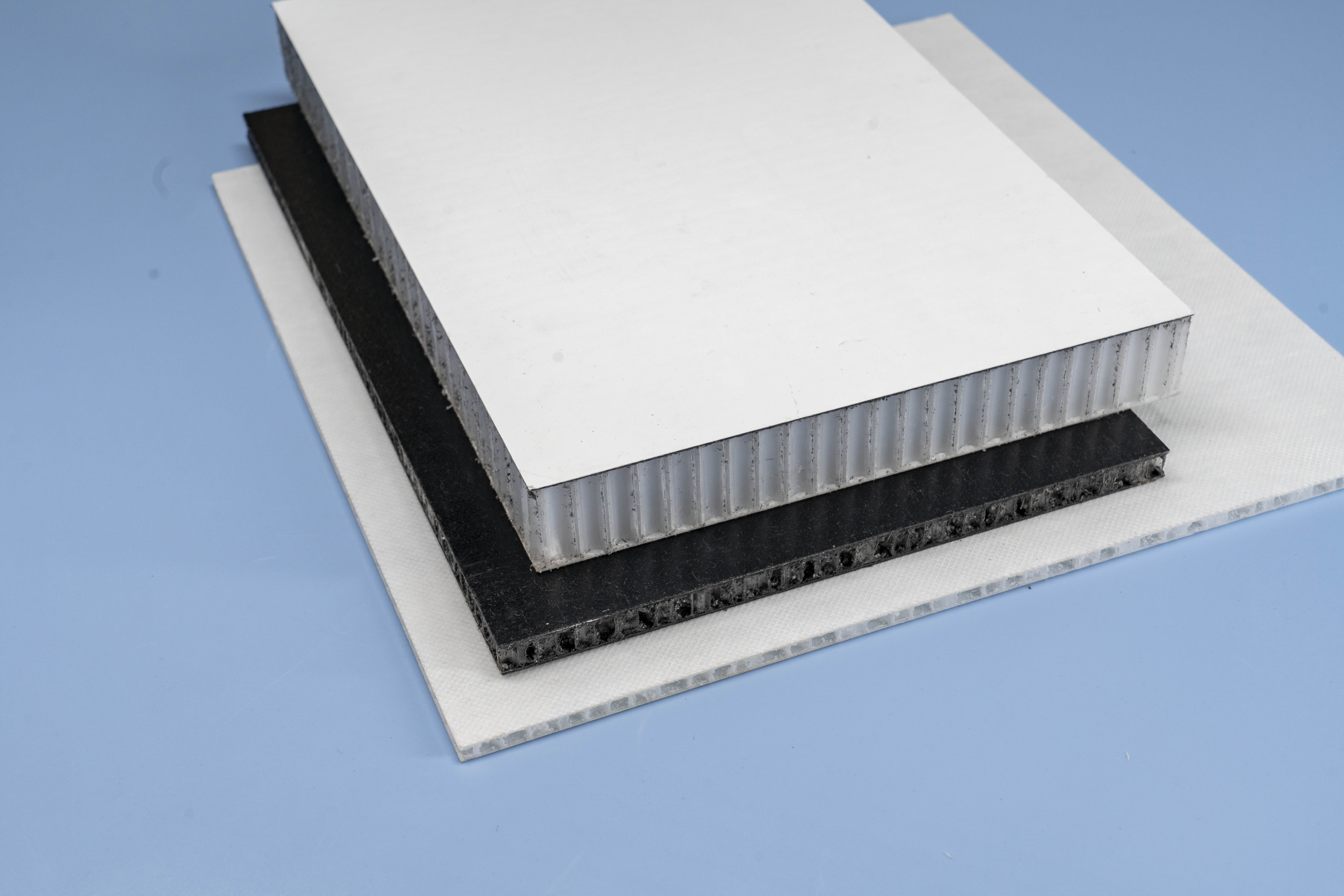

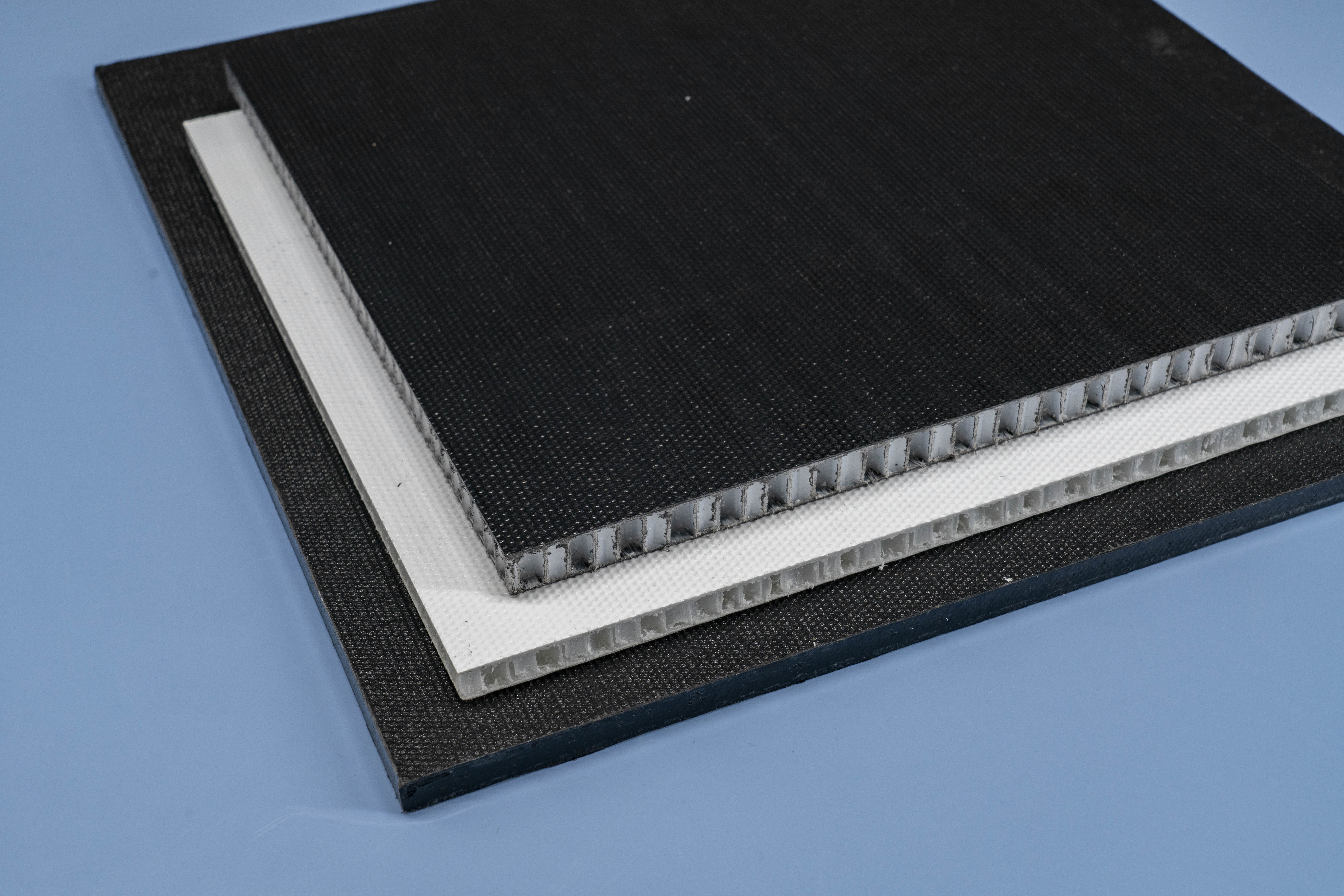

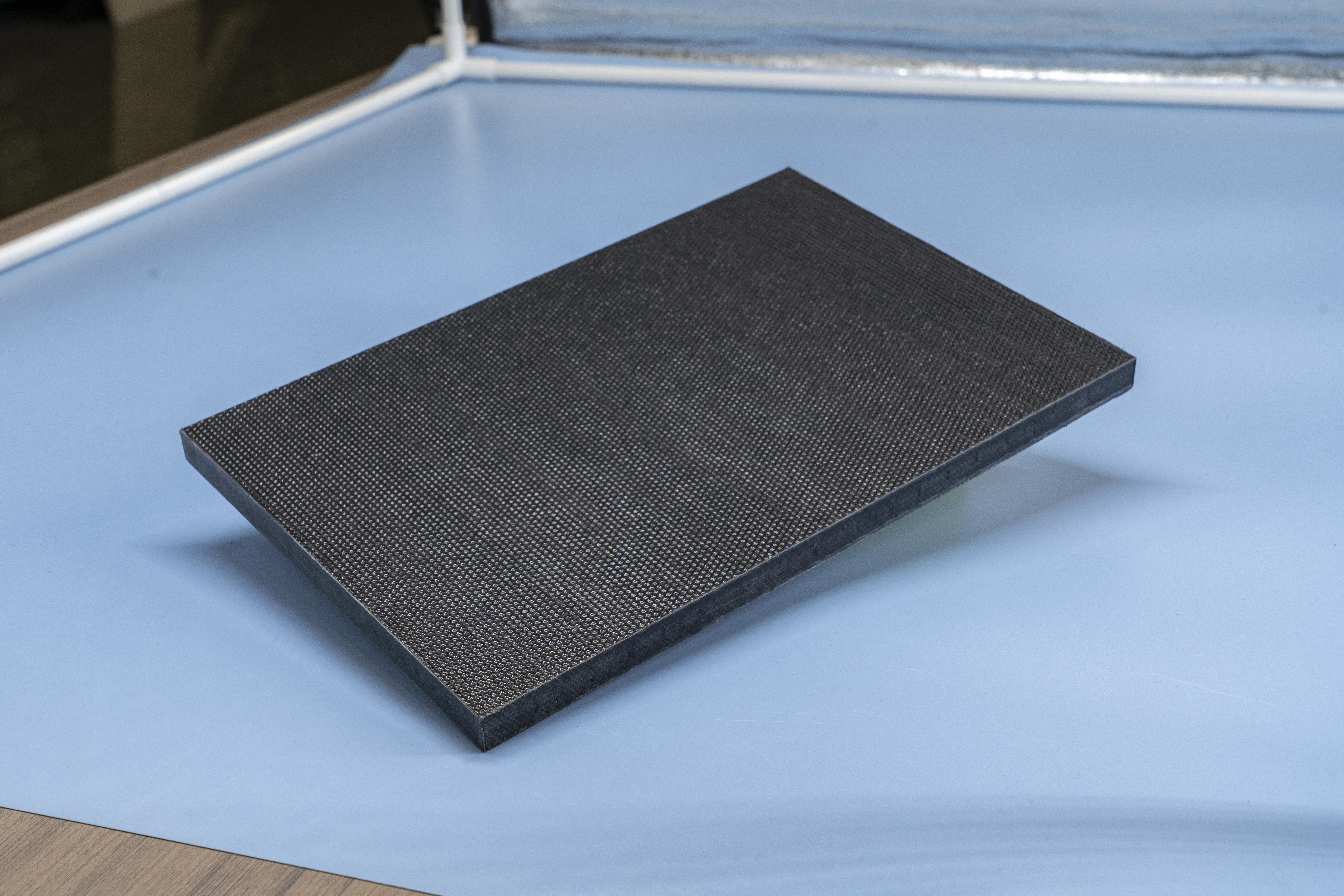

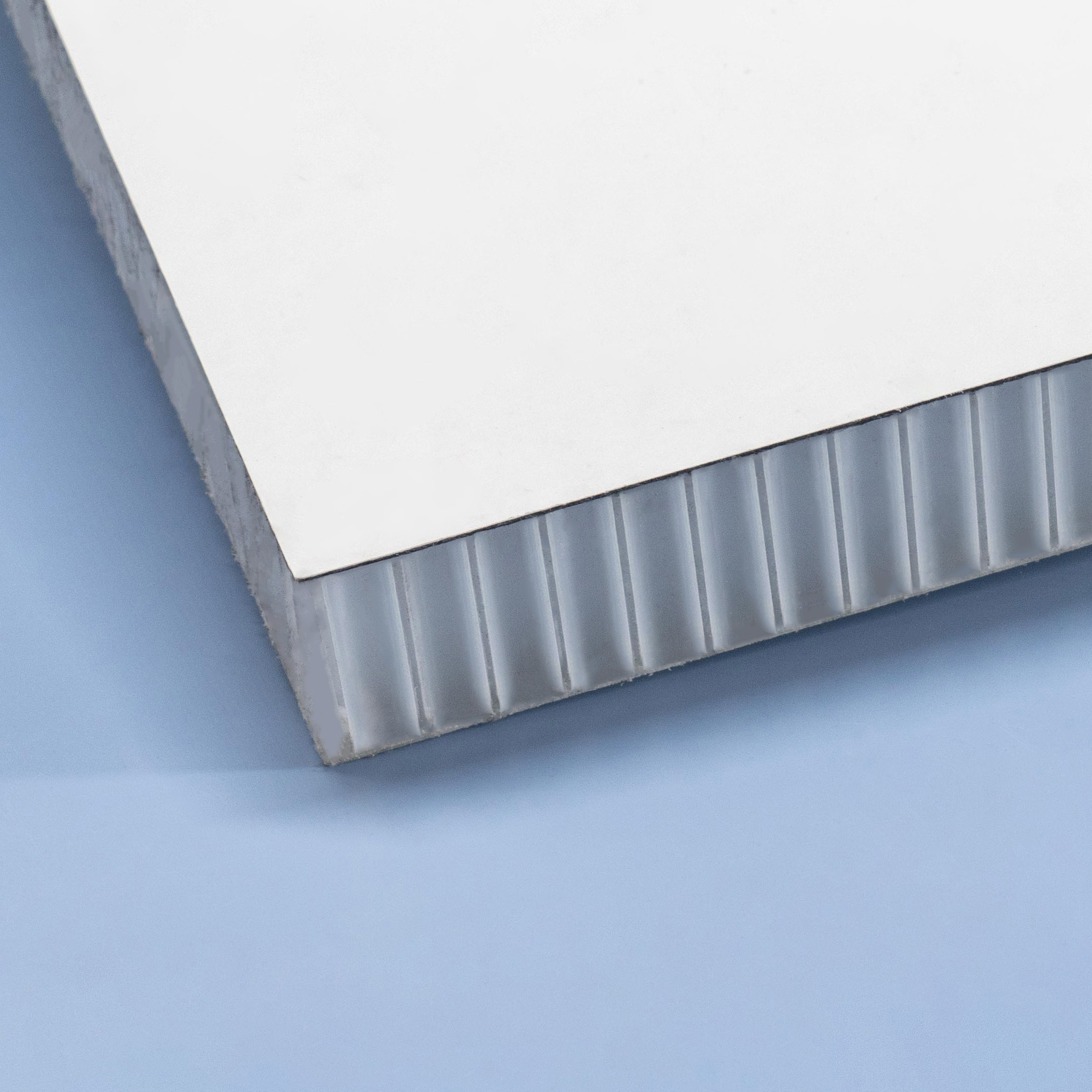

To put it simply, CFRT stands for Continuous Fiber Reinforced Thermoplastic. These panels are made by sandwiching a honeycomb core between two layers of continuous fiber reinforced thermoplastic. Sounds fancy, right? But here’s the kicker: this unique combination not only makes them remarkably sturdy but also super lightweight. Talk about a win-win!

Why Choose Continuous Fiber Reinforced Thermoplastic Honeycomb Panels?

Now, you might be wondering, “Why should I care about these panels?” Well, let’s break it down:

- Lightweight: These panels can weigh significantly less than traditional materials, which means easier handling and lower transportation costs. Who wouldn’t want that?

- Strength: Despite being lightweight, Continuous Fiber Reinforced Thermoplastic Honeycomb Panels pack a punch when it comes to strength. They’re designed to withstand high loads, making them ideal for rigorous applications.

- Durability: Resistant to moisture, chemicals, and UV rays, these panels are built to last. No more worrying about wear and tear!

- Design Flexibility: With a myriad of shapes and sizes, these panels can fit into various applications, from automotive parts to building facades.

Applications of Continuous Fiber Reinforced Thermoplastic Honeycomb Panels

Let’s not beat around the bush; the applications for Continuous Fiber Reinforced Thermoplastic Honeycomb Panels are as diverse as they are exciting! Here are a few sectors where these panels are making waves:

1. Aerospace

In the aerospace industry, every ounce counts. That’s why manufacturers are turning to Continuous Fiber Reinforced Thermoplastic Honeycomb Panels for aircraft interiors and structural components. Their lightweight nature means less fuel consumption and increased efficiency. It’s a no-brainer!

2. Automotive

In cars, weight reduction is key to improving fuel efficiency and performance. Continuous Fiber Reinforced Thermoplastic Honeycomb Panels are increasingly used in body panels, interiors, and even in electric vehicles, where every pound saved can enhance range.

3. Construction

From walls to roofs, Continuous Fiber Reinforced Thermoplastic Honeycomb Panels are revolutionizing the construction world. They not only reduce the overall weight of buildings but also improve thermal insulation and energy efficiency. Talk about a sustainable choice!

The Manufacturing Process

Curious about how these panels are made? The manufacturing process typically involves:

- Creating the honeycomb core, often from lightweight materials like aluminum or thermoplastics.

- Layering continuous fibers on both sides of the core, which are then infused with thermoplastic resin.

- Applying heat and pressure to bond everything together into a solid panel.

Voila! You’ve got yourself a Continuous Fiber Reinforced Thermoplastic Honeycomb Panel.

Challenges and Considerations

Of course, like any new technology, there are challenges. The initial costs can be higher than traditional materials, and the production process requires specialized equipment. But don’t let that rain on your parade; the long-term benefits often outweigh the upfront investment!

The Future is Bright!

As industries continue to seek out sustainable, lightweight materials, the demand for Continuous Fiber Reinforced Thermoplastic Honeycomb Panels is only expected to rise. With their unique properties and versatility, they’re paving the way for smarter, more efficient designs.

Conclusion

So, there you have it! Continuous Fiber Reinforced Thermoplastic Honeycomb Panels are not just a passing fad—they’re a game-changer in the world of materials. Whether you’re in the aerospace, automotive, or construction sector, these panels are worth your attention. So, the next time you hear about them, you’ll know you’re in for something special!

Key words:

Recommended News