PP/PET in CFRT UD Tape

Release time:

2025-02-11

Author:

Chengzi Tainuo

Source:

When it comes to CFRT (Continuous Fiber Reinforced Thermoplastics) UD (Unidirectional) Tape, the choice of materials, particularly PP (Polypropylene) and PET (Polyethylene Terephthalate), plays a crucial role.

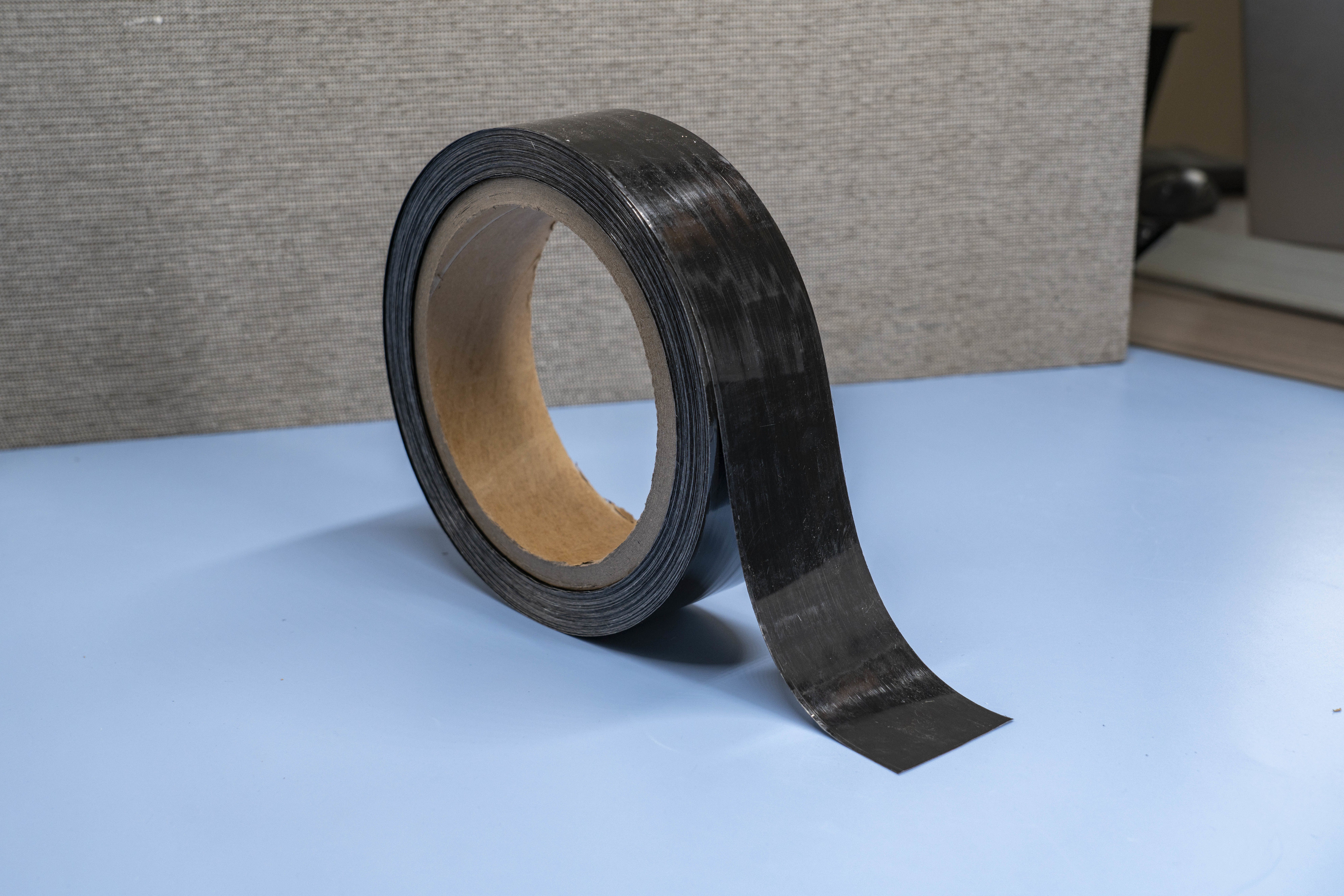

(PE UD Tape)

PP is widely favored for several reasons. Firstly, it offers excellent chemical resistance, enabling the CFRT UD Tape to withstand various harsh chemical environments. This property is vital in applications where exposure to corrosive substances is possible, such as in some industrial pipelines or chemical storage facilities. Secondly, PP has relatively low density, which contributes to the overall lightweight design of the composite. In industries like automotive and aerospace that constantly seek to reduce weight for better fuel efficiency or payload capacity, the use of PP-based CFRT UD Tape can be a significant advantage. Additionally, PP exhibits good processability, allowing for efficient manufacturing processes like extrusion and thermoforming, facilitating large-scale production.

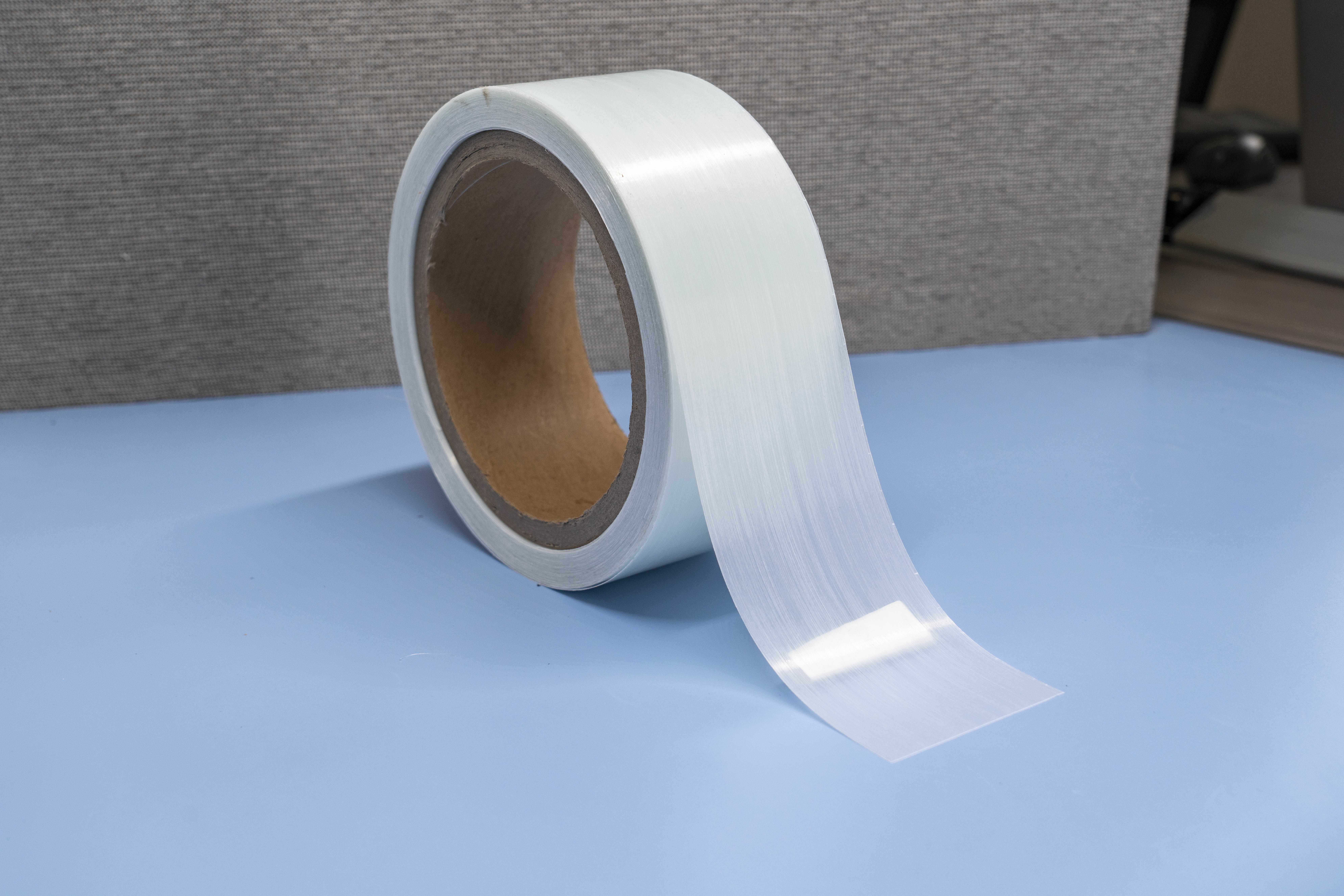

(PP UD Tape)

On the other hand, PET also has its own set of appealing characteristics. It provides enhanced mechanical properties, especially in terms of tensile strength and modulus. This makes PET a preferred option when the CFRT UD Tape needs to bear heavy loads or endure high stress conditions, for example, in structural components of buildings or in high-performance sporting goods. PET is also known for its dimensional stability, ensuring that the tape maintains its shape and size even under fluctuating environmental conditions, such as changes in temperature and humidity. Moreover, PET has better barrier properties compared to PP, which can be beneficial in applications where protection against moisture, gases, or other substances is essential, like in food packaging or electronic device encapsulation.

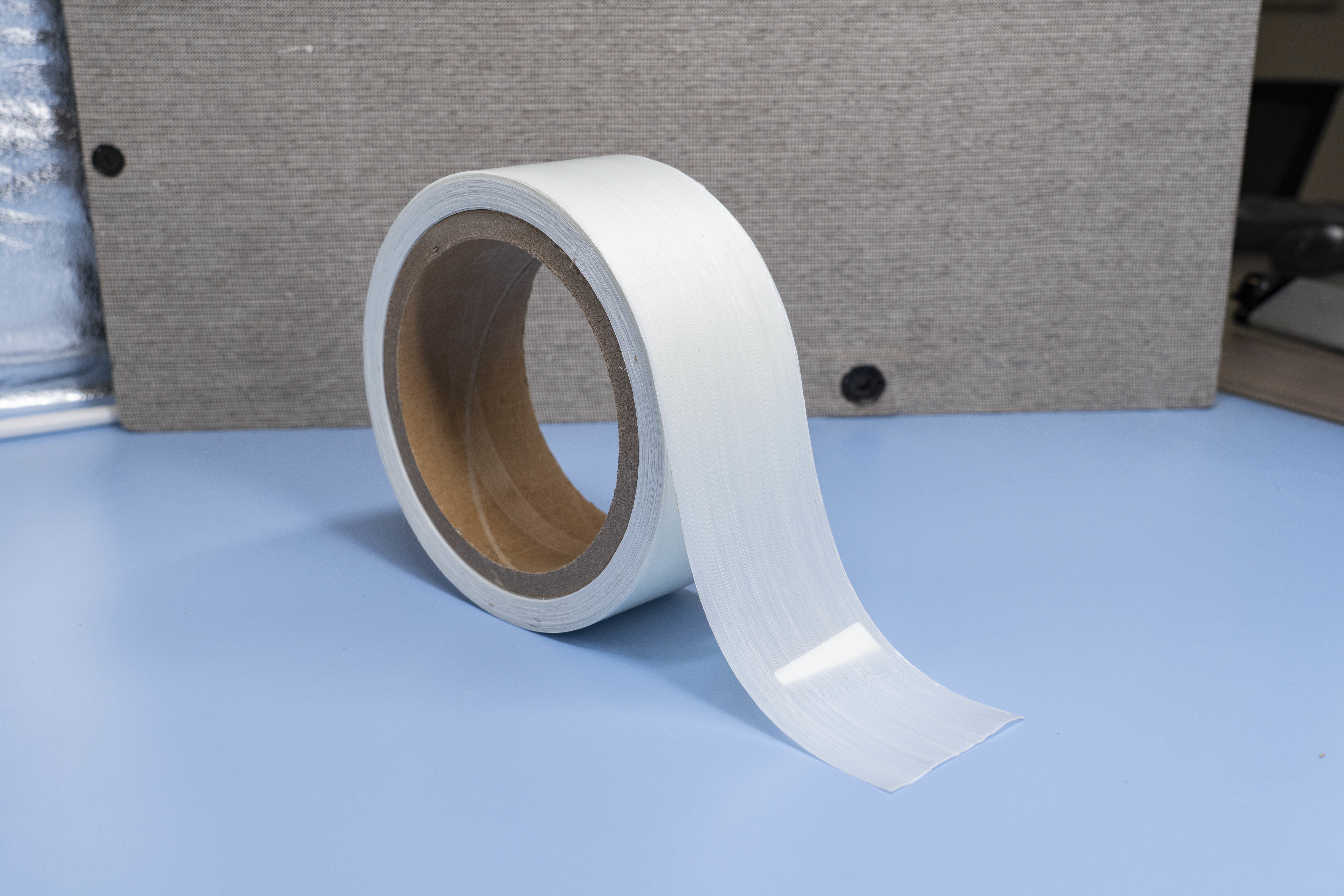

(PET UD Tape)

In conclusion, the selection between PP and PET in CFRT UD Tape depends on the specific requirements of the end application. Engineers and manufacturers need to carefully consider factors such as mechanical performance, chemical resistance, weight, and processing ease to make the most appropriate choice, thus optimizing the performance and functionality of the CFRT UD Tape in diverse fields.

Key words:

CFRT UD Tape

Previous Page

Recommended News