Categories

The main products of Chengzi Tainuo (Shandong) New Material Technology Co., LTD are based on continuous fiber-reinforced thermoplastic composites, including CFRT unidirectional prepreg tape, CFRT laminated sheets, CFRT sandwich panels (foam panels, honeycomb panels), etc.

Hot Products

Thickness:

0.15mm-1mm

Width:

25mm-750mm

Fiber type:

Continuous Glass Fibre, Basalt Fibre, Carbon Fibre, Aramid Fibre

If you are interested in our products, you can find us on the contact form below.

Get the latest product information

CFRT Container Thermoplastic Sheet Skin

Keywords:

CFRT Container Thermoplastic Sheet Skin

Affiliated Categories:

Thickness:

0.3mm-10mm

Width:

≤2850mm

Core material:

CFRT UD Prepreg Tape

Color:

White/Black, Other Colors Can Be Customized

Surface:

HUV Film /PET Film/Non-Woven Fabric Can Be Affixed

Application:

Container Skin

Description

|

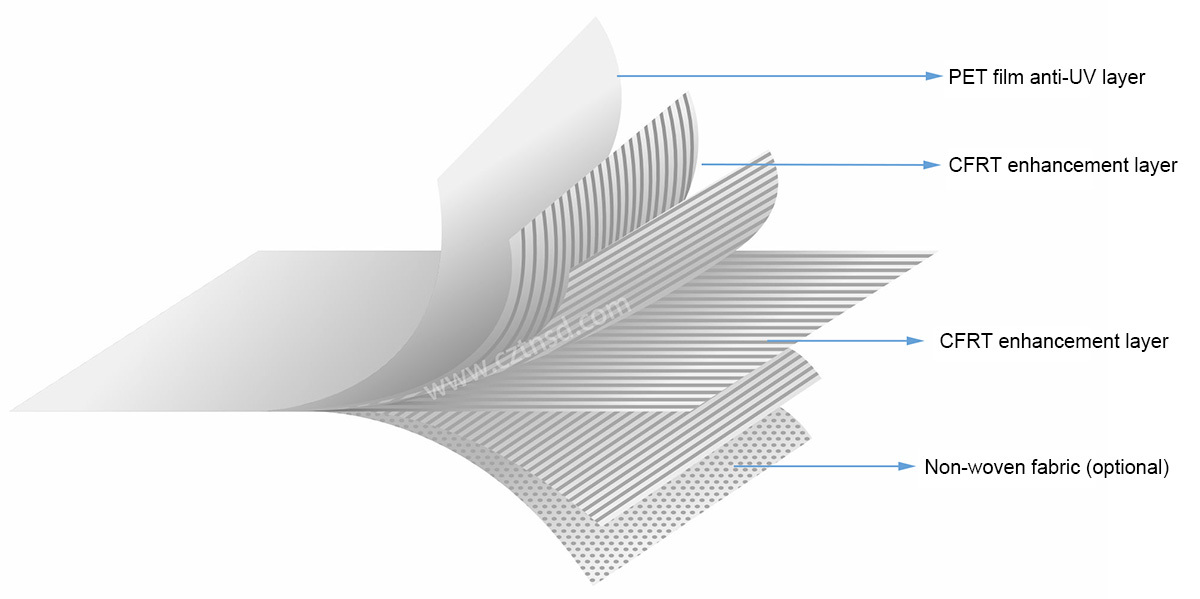

Product Description Made of continuous fiber-reinforced thermoplastic unidirectional tape with 0°/90° multi-layer cross-lamination, UV-resistant film on the surface and non-woven fabric on the back. |

|

Product Specification

Content Name: CFRT container thermoplastic sheet skinning

Product Name:Thermoplastic sheet skin

Sheet thickness: 0.3mm-10mm

Sheet width: ≤2850mm

Core material: CFRT UD prepreg tape

Sheet color: white/black, other colors can be customized

Surface effect: HUV film /PET film/non-woven fabric can be affixed

Application: Container skin

Product Features

The product has excellent performance, light weight and high strength, no odor, and at the same time can be bonded with different substrates, such as extruded plastic board XPS, polyurethane PU, polystyrene foam EPS, rock wool and other thermal insulation materials. The thermoplastic composite panel is specially designed and developed for the outer wall panel of refrigerated trucks, refrigerated containers, cold storage and other cold chain logistics, which can replace aluminum plate, stainless steel plate, color steel plate, fiberglass plate, etc. It has the characteristics of lightweight, high strength, high impact resistance, acid and alkali resistance, corrosion resistance, etc. In addition, the product is UV resistant for more than 7 years, and the surface can reach the U.S. FDA food grade

FAQ